How is clamshell packaging manufactured?

Thermoforming is a process of heating thermoplastic sheet and placing it over a mold until cooled. The thickness of the material determines whether the manufacturing process uses rolled sheets (thin gauge) or pre-cut stacked sheets (heavy gauge). Thin gauge material is dominant in the disposable packaging sector, especially in the retail markets. Heavy or thick gauge material is commonly used as permanent components in such things as refrigerators, automobiles and spas to name a few. PVC is the most commonly used material.

Thermoformed Packaging

Visipak manufacturers a wide variety of thermoformed packaging solutions that are ideal for nearly any product line. Listed below are several of our more popular options, which include clear plastic clamshells, blister packaging, and thermoformed tray inserts.

Clamshells

Blister Packaging

Thermoformed Trays

Engineering and Prototypes

Our multiple years of design experience has given us an advantage and often we advise clients of the best options for their applications. Using cutting-edge manufacturing techniques, our engineers will advise on material, process, and design to ensure the outcome is the most economical and efficient product.

Design

Not only do we have over 50 years of design experience, but we utilize some of the most sophisticated design and manufacturing software. We’ve grown in CAD CAM technology beginning in the early years of AutoCAD, then Pro-Engineer software.

Tooling

Collaborating with all our locations, we work seamlessly using PTC Creo and Siemens NX programs to seamlessly integrate the tooling fabrication process.

The Equipment

Our thin gauge, in-line thermoforming machines produce high volume quality parts from a variety of materials. The material moves through the heating section into the forming section where pressure and/or vacuum forces the material onto the mold. The process continues to the next station where the forms are die-cut.

Generally, vacuum forming refers to all sheet forming methods. Pressure aids vacuum forming to push the material into the mold. The added pressure of this process provides greater detail and textured surfaces in the end product. Creating sharp corners is possible with pressure added during the forming process.

Benefits of Thermoforming

Cost-effective Customization

Quick Turnaround Time

Inexpensive Molds

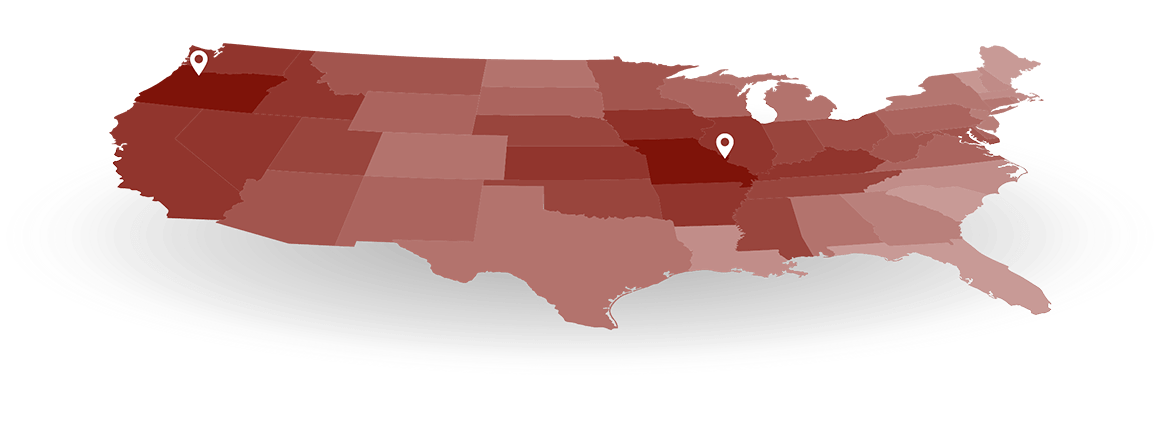

National Manufacturing Locations

As part of the Sinclair & Rush family of companies, we have thermoforming operations centrally located in St. Louis, Missouri and on the west coast in Portland, Oregon. Our line of stock clamshell packaging is available nationwide. Likewise, our custom solutions are manufactured in all locations. We are manufacturers of precision clamshell packaging and thermoformed trays.